We continue to absorb and digest the advanced technology at home and abroad. The product standards can be in line with the international standards and can be converted into various standards.

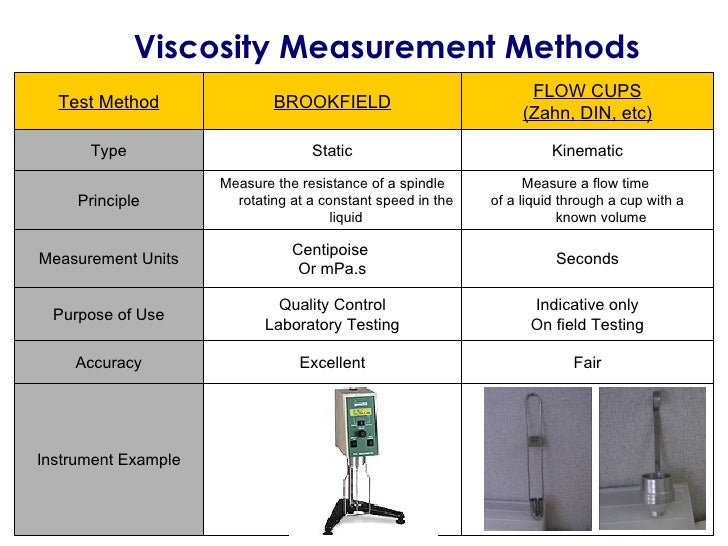

Our deep understanding of technology and excellent processing ability make our product quality different. Our company has many years of experience. To see an example of one such exciting development, read the article, Viscosity Index Analyser for Optimal and Cost-Effective Refining Operations, which talks about the advantages of a new product released earlier this year.In the future development, we will continue to adhere to the path of specialization, carry out technological innovation, and strive to promote the development of petroleum colorimeter, impulse voltage test system, cloud and pour point apparatus. Over the years viscometers have become more and more sophisticated. The former is much more prevalent in terms of measuring an oil’s viscosity. In layman’s terms, the former measures how quickly the oil will flow, whilst the latter determines how easily it can be stirred. The two main methods of oil testing in a laboratory are the capillary tube viscometer method, which measures kinematic viscosity, and the rotary viscometer method, which measures absolute viscosity. The above process is a difficult and unreliable one, and to achieve a more dependable figure, testing in a laboratory is advisable. The longer it takes for the oil to rise and fall, the more viscous the oil.When it reaches the end, remove the seal and record how long it takes to fall. Using a stopwatch, record how long it takes for the heated water to raise the oil’s temperature enough that it rises to the sealed end of the tube.Submerge an open-ended U-shaped glass tube in the water, so that the bend is submerged, but the ends are open to the air.Maintain the temperature throughout the test. The water should be deep enough to submerge an object, but not overfilled so that it will spill. Fill a container with water and boil to 100°.The process is a complicated and potentially dangerous one, and so should not be undertaken without extreme care and the correct equipment and safety measures: Here is how: Testing Oil Viscosity at Home Manufacturers provide this information by placing grades or data on the bottle itself.Īn Oil’s viscosity can be determined in a laboratory or even at home. Since the viscosity of an oil will affect how efficiently it can achieve this objective, users must be aware of an oil’s viscosity before using it. One of the main functions of oil is as a lubricant in machinery or vehicles - t prevents them from overheating, and as a result, becoming welded together.

An oil with a higher viscosity will generally be thicker and take a longer time to succumb to gravity. Oil viscosity - how oil flows as a result of gravity - is one of its most important properties.

0 kommentar(er)

0 kommentar(er)